Why do aluminum alloy profiles need to be packaged?

Aluminum profiles are products made from aluminum and other alloy elements. The processed aluminum profiles must be packaged to avoid damage such as bumps during later handling or transportation. Due to the high quality requirements of aluminum alloy profiles and the high emphasis on overall aesthetic appearance, strict packaging requirements are required in the later stage.

Generally, aluminum profile manufacturers, in order to protect aluminum profiles from damage during transportation, strictly package them before shipment. Aluminum profile packaging is the final process and also a subject of knowledge. All the previous processes have been completed, and it is not allowed to cause scratches or other problems during transportation due to poor packaging. This will also cause significant losses to the aluminum profile manufacturers and customers, So what are the general packaging methods for aluminum profiles?

Packaging process for aluminum alloy profiles:

1. Firstly, it is a direct bundling method, which involves bundling the processed aluminum alloy profiles into bundles according to a certain quantity. These bundles do not require high surface requirements for the profiles, and the product structure is relatively regular, so direct delivery does not require any transfer. Customers usually request direct shipment for the remaining packaging fees.

2. Then there is packing in wooden boxes, which can prevent aluminum profiles from being damaged during transportation.

3. Another option is single cotton packaging, which involves separating individual products with pearl cotton and repackaging several aluminum alloy profiles. This can also be divided into several forms. Generally, aluminum profiles with surface oxidation treatment need to be wrapped with pearl cotton first and then with Kraft paper. If the substrate is used, there is no need to wrap it with pearl cotton, just wrap it with Kraft paper. For profiles with particularly high surface requirements, it is necessary to first apply a film and then wrap them with pearl cotton and Kraft paper.

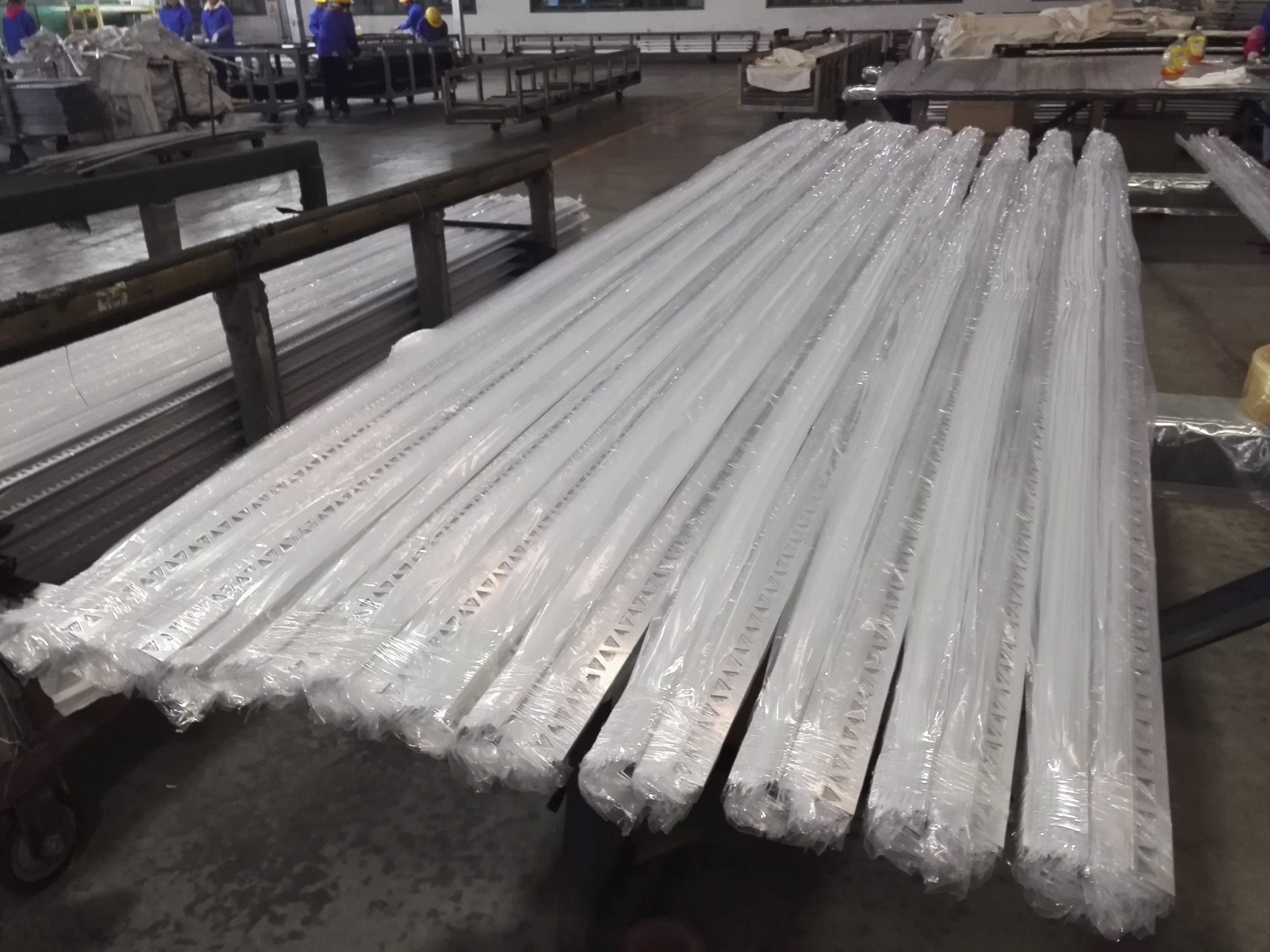

4. For short materials that have been swan and processed, they can be wrapped with pearl cotton first, placed on a tray, wrapped tightly with wrapping film, and directly loaded onto the truck after being packaged with a strapping tape. This can greatly reduce the damage rate of aluminum alloy profiles.

What are the benefits of packaging aluminum alloy profiles in wooden boxes?

There are many packaging methods for aluminum alloy profiles, such as Kraft paper and air cushion film, but the position of wooden box packaging in transportation is also unshakable. Many aluminum profile processing plants use wooden box packaging for bulk transportation. So, what are the benefits of using wooden box packaging for aluminum alloy profiles?

1. Protecting the wooden box packaging of goods can gather scattered aluminum profiles together, reducing the compression of aluminum during transportation.

2. Mechanized loading and unloading can be carried out by workers who can operate transport vehicles to transport large quantities at once, reducing aluminum loading and unloading time and labor intensity.

3. Reducing the volume of packaging can store various aluminum profile accessories in a wooden box, greatly increasing the storage space of aluminum profile factory warehouses.

4. Save packaging costs. Wood is relatively cheap, and wooden boxes can be used multiple times, saving packaging costs for aluminum profiles.

5. For easy counting, simply open the wooden box to purchase clear aluminum materials for counting.