In the field of decoration and renovation, a small yet crucial product is often overlooked - L-mouldings. As the "unsung heroes" for handling space corners and enhancing the appearance's level, L-mouldings have become common materials in home, commercial spaces, and industrial settings due to their flexible adaptability and practical functions. Choosing reliable L-mouldings suppliers is the core prerequisite for ensuring product quality and usage effectiveness.

What are L-mouldings?

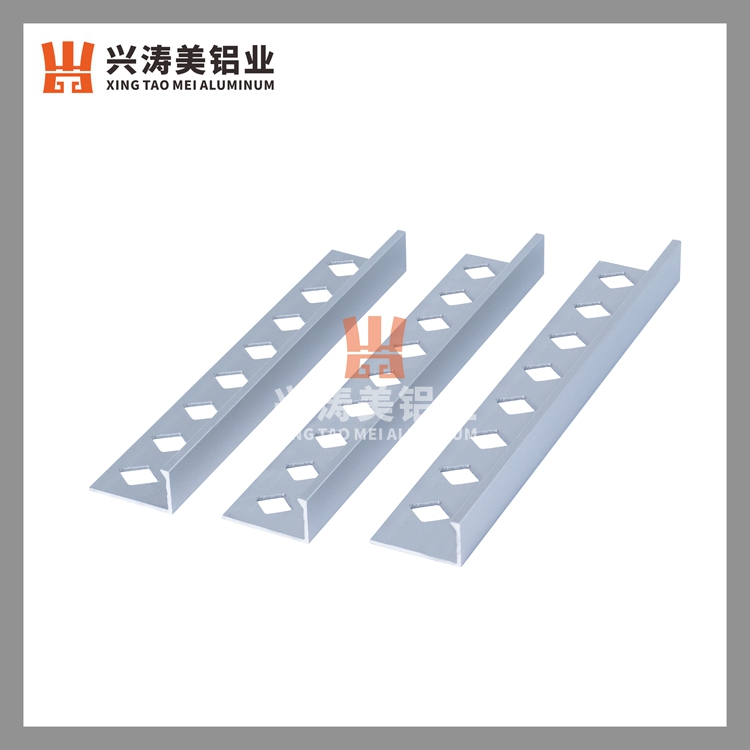

L-mouldings, as the name suggests, are decorative profiles with an "L" shaped cross-section. They are commonly made of aluminium, which is light, durable and easy to process, making aluminium L-mouldings the mainstream in the market. They can cover the corners and gaps of walls, furniture and floors, solving the problem of "rough edges" and "leaking seams" after decoration. Moreover, through the combination of colors and textures, they can add a sense of layering to the space. Unlike ordinary decorative accessories, L-mouldings have both "protective" and "decorative" functions: for example, L-mouldings on the corners of furniture can prevent damage from collisions, and L-mouldings at the junction of walls and ceilings can hide construction errors, making the overall decoration more refined.

Core Applications of L-Mouldings, Covering Diverse Scene Requirements

The application scenarios of L-mouldings are far more extensive than imagined, ranging from daily home settings to commercial spaces and even industrial fields. In home decoration, it can serve as a transition strip between floors and tiles, preventing wear at the junction of the two materials; it can also be used as a corner trim for cabinets and wardrobes, making the edges of furniture smoother and reducing the risk of bumps. In commercial spaces such as shopping malls and hotels, L-mouldings are often used to outline display cabinets and wall designs, enhancing the high-end feel of the space through metallic textures or custom colors. Even in industrial settings, L-mouldings can play a role - as corner protection strips for equipment shells, increasing the durability of the equipment. These diverse uses make L-mouldings a "must-have" in various fields, and also prompt more people to pay attention to the selection of high-quality L-mouldings manufacturers.

Advantages of L-mouldings: Why They Are the Preferred Choice for Decoration?

Choosing L-mouldings essentially means choosing its multiple advantages. Firstly, it is durable, especially aluminum L-mouldings, which are resistant to corrosion and rust. Even when used in damp environments such as kitchens and bathrooms, they can maintain stable performance for a long time, avoiding deformation or discoloration due to moisture, which affects aesthetics. Secondly, it has a high level of appearance adaptability. High-quality L-mouldings manufacturers can provide a variety of surface treatment processes, such as anodizing, spraying, and brushing, which can match different decoration styles such as wood, tiles, and latex paint, and also meet personalized color requirements, allowing the decorative strips to blend into the space rather than being "out-of-place accessories". Thirdly, it is easy to install. The structural design of L-mouldings is simple and does not require complex construction processes. Whether installed simultaneously during decoration or supplemented during later renovations, it can be completed quickly, reducing time and labor costs. Finally, it has a good cost performance. Aluminum L-mouldings have a long service life and do not need to be replaced frequently. In the long run, it can reduce maintenance costs, which is also an important reason why it is favored by many users.

How to Choose the Right L-mouldings Suppliers? Three Key Points to Consider

When faced with a multitude of L-mouldings suppliers in the market, how to select reliable partners? The key lies in three aspects: production capacity, quality assurance, and customization ability. First, high-quality L-mouldings suppliers usually have a complete production system - for instance, they possess professional melting, casting, extrusion, and deep processing equipment, enabling full control over the process from raw materials to finished products, thus avoiding quality instability caused by outsourcing. Second, quality assurance is the bottom line. Legitimate L-mouldings manufacturers typically obtain certifications such as ISO9001 for quality management systems, and their products undergo strict inspections to ensure that each batch of decorative strips meets standards in terms of dimensional accuracy, surface flatness, and durability. Lastly, customization ability is indispensable. Different scenarios may have varying requirements for the size, color, and processing of L-mouldings. Only L-mouldings suppliers that offer personalized customization services can better meet diverse demands and avoid waste due to "standardized products" being unsuitable for actual scenarios.

Foshan Xingtaomei Aluminium: A Trustworthy L-mouldings Supplier and Manufacturer

Among numerous L-mouldings Suppliers, Foshan Xingtaomei Aluminum Industry Co., Ltd. has emerged as a reliable choice in the industry, thanks to its solid production capabilities and high-quality product offerings. As a professional Aluminium Profiles Manufacturer, Xingtaomei Aluminum Industry focuses on the production of high-quality industrial aluminum profiles and customized decorative aluminum profiles. Its L-mouldings products cover multiple fields including home, commercial, and industrial, meeting the usage requirements of various scenarios.

In terms of production capacity, Xingtaomei Aluminum Industry has a 30,000-square-meter factory area, equipped with 2 melting and casting furnaces, 8 extruders, and a complete anodizing production line. It also has professional punching and drilling deep processing equipment, enabling it to achieve full-process independent production from aluminum profile melting and casting, extrusion molding to later deep processing. With an annual output of over 20,000 tons, it can promptly respond to customers' bulk order demands while avoiding quality risks in intermediate links. In terms of product quality, the company has passed ISO9001 quality management system certification and CQM certification, and has also won multiple honors such as "National High-tech Enterprise" and "Contract-abiding and Creditworthy Enterprise". Behind these qualifications and titles lies strict control over every L-molding - from raw material selection to production process supervision, and then to finished product inspection, every step adheres to high standards to ensure the durability, flatness and appearance level of the products.

More importantly, Xingtaomei Aluminium has a strong ability to customize products. Whether it is adjusting the size of L-mouldings, customizing surface colors (such as matte black and champagne gold to match specific decoration styles), or special process requirements (such as brushing and sandblasting), the company can provide solutions based on the specific needs of customers, making L-mouldings no longer "uniform standard parts", but "customized products" that precisely fit the space decoration. As a reliable L-mouldings supplier, Xingtaomei Aluminium always adheres to the concept of "creating value for partners", and uses solid production strength and high-quality products to provide customers with all-round support from products to services.