What Are Aluminium Profiles? Are you just like me who felt a sense of curiosity the first time you saw the term Aluminium Profiles?

Because in our perception, the terms used for aluminium include aluminium materials, aluminium alloys and the like, yet very few people are familiar with Aluminium Profiles. However, once we actually come across the term Aluminium Profiles, we can’t help but feel curious and want to find out more about it.

If you too are currently looking to understand What Are Aluminium Profiles?, then the following content is sure to be of help to you.

1. The Basic Definition of Aluminium Profiles

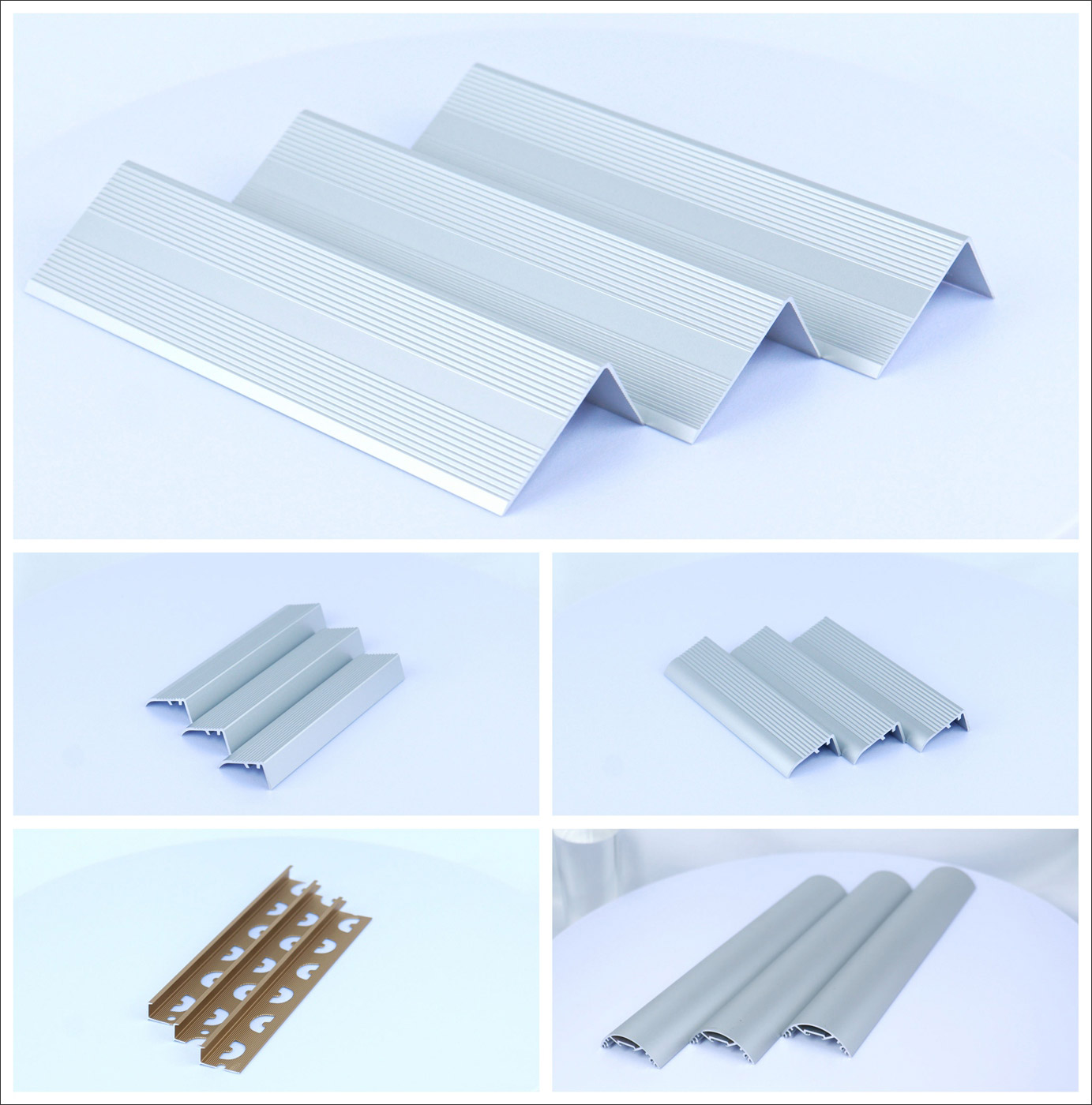

At their core, Aluminium Profiles are extruded or shaped products made from aluminium alloys (aluminium mixed with small amounts of other metals like silicon, magnesium, or copper to boost strength). Unlike solid aluminium blocks or sheets, profiles are designed with specific cross-sectional shapes—such as rectangles, channels, T-bars, or custom designs—to fit particular applications.

The manufacturing process (explained below) ensures Aluminium Profiles retain aluminium’s natural advantages (lightweight, corrosion-resistant) while adding structural integrity. This makes them far more adaptable than raw aluminium: a single profile can serve as a support beam, a frame component, or a decorative trim, depending on its shape and finish.

2. Key Characteristics of High-Quality Aluminium Profiles

Not all Aluminium Profiles are the same—high-quality ones share critical traits that make them reliable for long-term use:

Strength-to-Weight Ratio: Aluminium is already 1/3 the weight of steel, but profiles (especially alloy-based ones) maintain impressive strength. This means Aluminium Profiles can support heavy loads (like window glass or industrial machinery) without adding unnecessary weight.

Corrosion Resistance: Pure aluminium forms a protective oxide layer, and profiles often get extra treatments (e.g., anodizing, powder coating) to resist rust, moisture, and chemicals. This makes Aluminium Profiles ideal for outdoor use (e.g., building facades) or humid environments (e.g., kitchen cabinets).

Customizability: Manufacturers can extrude Aluminium Profiles into nearly any cross-section, from simple tubes to complex, brand-specific shapes. This flexibility lets designers tailor profiles to unique project needs.

Sustainability: Aluminium is 100% recyclable, and recycling it uses 95% less energy than producing new aluminium. Many Aluminium Profiles are made from recycled materials, making them an eco-friendly choice for green projects.

3. How Aluminium Profiles Are Made (Key Manufacturing Steps)

The production of Aluminium Profiles centers on extrusion—the most common method for creating their distinct shapes. Here’s a simplified breakdown:

Alloy Preparation: Aluminium ingots are melted with other metals (e.g., magnesium for strength) to create the desired alloy. This molten alloy is then cast into "billets" (cylindrical blocks) for extrusion.

Extrusion: A billet is pushed through a steel die (with the target cross-section) under high pressure (up to 10,000 psi). As the metal exits the die, it takes the die’s shape—forming the basic Aluminium Profile.

Cooling & Aging: The extruded profile is cooled quickly (via water or air) to set its shape. For added strength, some profiles undergo "aging" (heating at low temperatures) to harden the alloy.

Finishing: Finally, Aluminium Profiles get surface treatments like anodizing (for a matte, scratch-resistant finish), powder coating (for color options), or polishing (for a sleek look). These steps enhance durability and aesthetics.

4. Common Applications of Aluminium Profiles

Thanks to their versatility, Aluminium Profiles are used across nearly every industry. Here are the most popular use cases:

Construction: Windows, door frames, curtain walls, and ceiling grids often rely on Aluminium Profiles—their lightweight nature eases installation, and corrosion resistance stands up to weather.

Automotive: Car manufacturers use profiles for body frames, door beams, and heat sinks. The weight savings from Aluminium Profiles helps improve fuel efficiency.

Furniture & Interior Design: Shelving units, wardrobe frames, and office partitions frequently use Aluminium Profiles—they’re sleek, easy to assemble, and resistant to wear.

Industrial & Electronics: Conveyor belts, machine frames, and LED heat sinks depend on Aluminium Profiles for their strength and heat-dissipating properties.

5. Why Choose Aluminium Profiles Over Other Materials?

When comparing Aluminium Profiles to alternatives like steel, wood, or plastic, they stand out for several reasons:

vs. Steel: Aluminium Profiles are lighter (reducing transportation and installation costs) and don’t rust—no need for regular painting or maintenance.

vs. Wood: Profiles resist rot, termites, and moisture, making them better for outdoor or high-humidity spaces. They also won’t warp or splinter over time.

vs. Plastic: Aluminium Profiles are stronger and more heat-resistant, so they’re suitable for heavy-duty or high-temperature applications (e.g., industrial machinery).

By this point, it is believed that everyone has gained a general understanding of What Are Aluminium Profiles, as well as some of the characteristics and applications of Aluminium Profiles.

In fact, the Q&A Column on our Xingtaomei Official Website (www.xtm-trims.com) features a wealth of professional knowledge related to Aluminium Profiles, along with answers to questions posed by netizens. If you have an interest in Aluminium Profiles, you can also visit the website to learn more about the topic. Next, we would also like to recommend some content that may be of interest to you regarding Aluminium Profiles:

1. What Is Aluminium Trim? Where Is Aluminium Trim Needed?

2. What colors can industrial aluminum alloy profiles be made?

About Us

Foshan Xingtaomei Aluminum Industry Co., Ltd., a professional Aluminium Profiles Manufacturer, was founded in 1996. As one of the reliable Aluminium Profiles Suppliers in South China’s aluminium industry cluster, we focus on the R&D and production of high-quality industrial Aluminium Profiles and customized Decorative Aluminium Profiles. Our product portfolio covers diverse categories, including lighting profiles, furniture profiles, tile trims, floor transitions, as well as standard Aluminium Profiles such as tubes, bars, U-trims, and L-trims—fully meeting the needs of industrial manufacturing and decorative application scenarios.